Efficient 4 Cavity Automatic Servo Bottle Blow Molding Machine

Efficient 4 Cavity Automatic Servo Bottle Blow Molding Machine

2024/3/28 , visitsPET blowing machine for 2l linear bottle blowing machines are used in the production of PET water bottles, hot filling bottles, carbonated beverage bottles, edible oil bottles, and pesticide bottles.

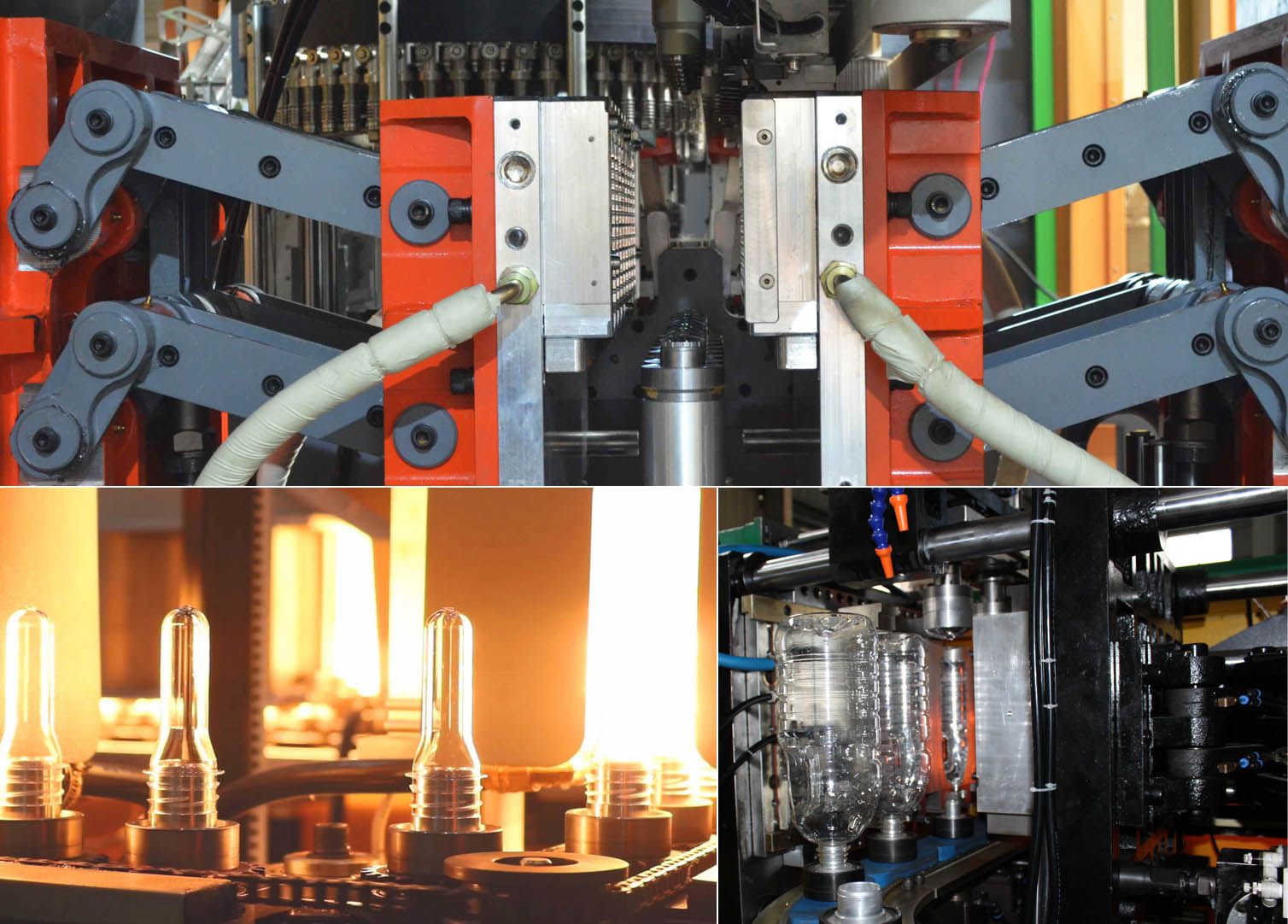

Meto Machinery's linear bottle blowing machine stretches preforms by using a servo motor-controlled stretch rod. The advantage is that it can be stretched in sections,and positioning of the preform is at first in order to ensure the verticality of the preforms during stretching, then secondary stretching.

Ensure the uniformity and consistency of each preform stretching.At the same time,bottle blowing machine has a fast stretching speed and precise position.

Sufficient InventoryWith a standardized workshop covering a total area of 20,000 square meters, we maintain ample spare parts inventory for timely delivery.All equipment undergoes a 24-hour test run before leaving the factory to ensure mechanical components stability.

Professional TrainingProfessional installation team will visit your factory to install the machines and train your staff . Additionally offer free video training sessions.

High positioning accuracy, fast speed and stability, good reliability. Gas circuit design will divide action and blowing into three parts to meet the needs of different pressure for blowing bottles and movement; Adopt high pressure and double crank arm link locking, strong clamping force.

Adopt infrared lamp heating

Adopt infrared lamp heating, strong penetration, preform rotation heating, track revolution, heating evenly, fast and reliable; Heating lamp, reflector width and height can be adjusted to suit preform heating of different structure, with automatic temperature-removal device to ensure the constant temperature of oven.

Auto-loader

Auto-loader improves working efficiency, accurate transportation, reliable and durable, raw materials are completely free of moisture, pollution, foreign matter, and loss during feeding process. Realize transportation process of feeding process, avoid danger of high-altitude feeding, reduce labor intensity and increase production efficiency.

Intelligent Human-Machine Interface

1.Human-machine interface control, easy operate and monitor.

2.Live production information supervise, auto record production data everyday

3.Failure warning and troubleshooting.

| Item |

MT-6000 | |

| Bottle type specification | Cavity | 4 |

| Theory output | 6000 bph | |

| Max.volume | 2L | |

| Bottle mouth maximum overall diameter | 28-38mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximum height | 330mm | |

| Power specification | Light tube quantity | 40pcs |

| Light tube power | 1.5KW | |

| Maximum heating power | 60KW | |

| All electric machine installation | 91KW | |

| Actual consumption | 70KW | |

| Air pressure specification | Work pressure | 7-9kg/c㎡ |

| Low-pressure gas consumption | 1600L/min | |

| Blow bottle pressure | 25-35kg/c㎡ | |

| Higher -pressure gas consumption | 6000Ltr/min | |

| Air pressure specification |

Work pressure | 5-6 kg/c㎡ |

| Temperature range | 10℃ | |

| Consumption | 8000kcal/hr | |

| Frozen water flow | 138L/min | |

| Machine specification | Machine size | 4.05x2.16x2.45 |

| Machine weight | 4.3ton | |

Plastic Bottle Making Machine Manufacturers,PET Bottle Blowing Machine

With over a decade of manufacturing experience in the automatic PET blowing machine industry, we are confident with our high-quality products helping you achieve your company goals. Allow METO Machine to supply your bottle-making machine requirements and experience the superior difference with our advanced equipment.

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

ENTERPRISE STRENGTH

We are a bottle blowing machine manufacturer. We are committed to offering customized solutions for the market and customers, whether individual products or complete sets of equipment. Although the market, application, and customers are different, we have a unique concept to guide the success of customers.

- We will respond patiently and carefully to any consultation and feedback from customers.

- For any inquiry from customers, we will give you a professional and reasonable quotation.

- For any new products of our customers, we will communicate with our customers very professionally, listen to the opinions of our customers and give useful suggestions to ensure the quality of our products.

- After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

- After the commissioning, we will package the equipment by standard export package for shipment.

- According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

- Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Product Features

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

- Less than 0.2% scrap rate for finished bottle.

Bottle blowing machine video

Helpline and Support

008613757660057