High speed PLA Semi auto 4 cavity PET bottle blowing machine / Plastic Bottle Blower

High speed PLA Semi auto 4 cavity PET bottle blowing machine / Plastic Bottle Blower

2024/3/29 19:32:20 , visitsOverview

Semi auto 4 cavity PET bottle blowing machine / Plastic Bottle Blower

Summary

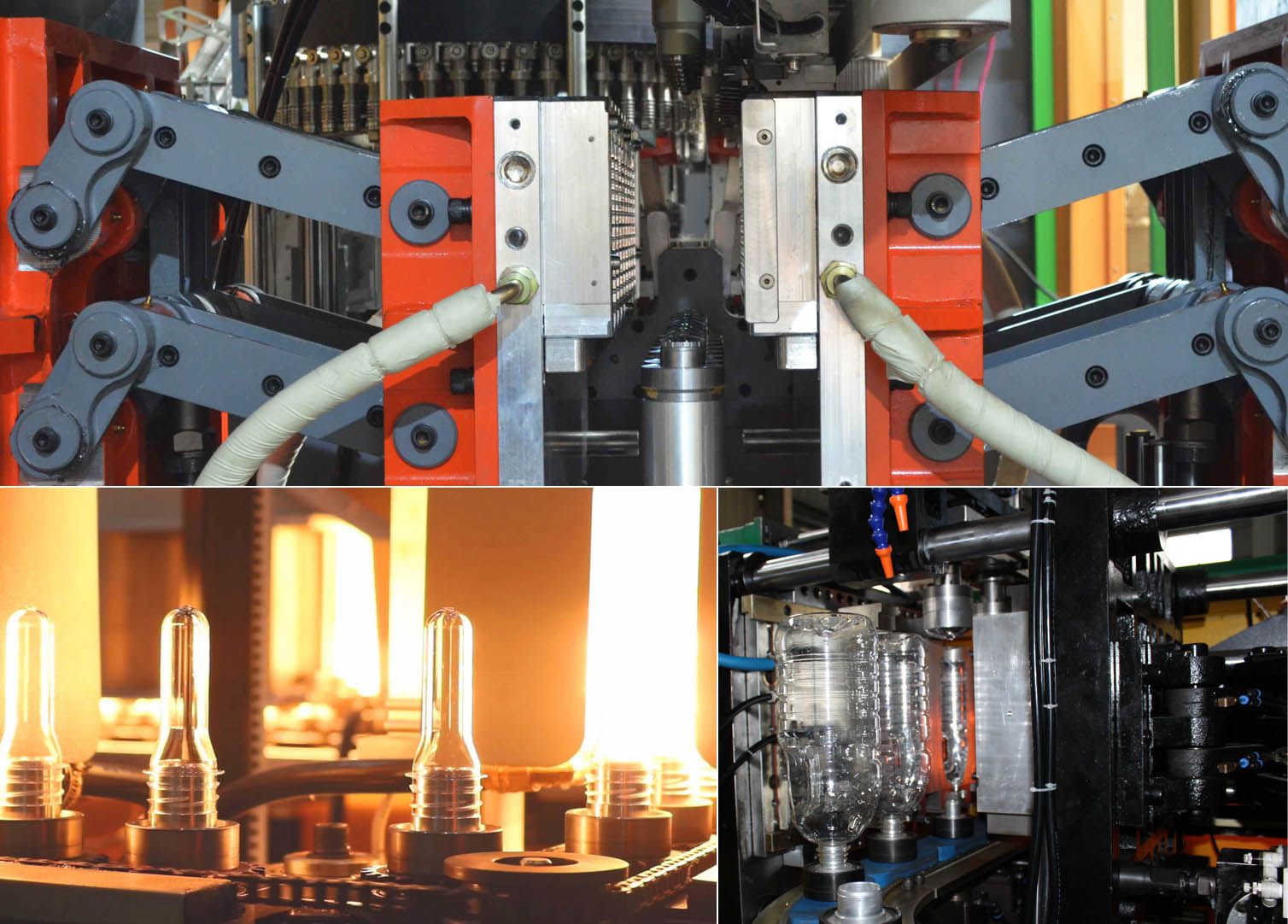

4 Cavity Semi Automatic Blowing Machine, blowing the bottle max to 1.5L, used for the series kinds of PET-PP bottle, such as the edible oil bottle,medicinal bottle, drinking bottle,cosmetic jars, Wild-mouth bottle and so on.

Technical Parameter:

| spec | MT-C2L-4T | ||

|

bottle size |

Max. Bottle capacity | ml | 1.5L |

| center distance | mm | 120 | |

| Max.neck outer diameter | mm | 45 | |

| Max.body diameter | mm | 110 | |

| Max.bottle Height | mm | 350 | |

| Cavity No. | 4 | ||

| Output | BPH | 2800-3000 | |

| electrical equipment | Installed capacity | Kw | 30 |

| Max.heating power | Kw | 20 | |

| air compression | Operating pressure | Mpa | 0.8 |

| Low pressure oxygen consumption | M3/min | 0.9 | |

| Blowing pressure | Mpa | 3.0 | |

| High pressure oxygen consumption | M3/min | 1.1 | |

| Chiller | pressure | Mpa | 0.3-0.5 |

| Temperature | ℃ | 12-18 | |

| Flow | L/min | 30 | |

| machine | dimension(L*W*H) | m | 2.6X1. 3X1.8 |

| Weight | Kg | 1.9 t | |

Plastic Bottle Making Machine Manufacturers,PET Bottle Blowing Machine

With over a decade of manufacturing experience in the automatic PET blowing machine industry, we are confident with our high-quality products helping you achieve your company goals. Allow METO Machine to supply your bottle-making machine requirements and experience the superior difference with our advanced equipment.

The main parts of The machines are from Germany, Japan, Switzerland, Korea, Taiwan and so on, They can make 10ml-25L bottles and barrels and jars with different designs and shapes with PET, PP, PE and other material. Our machines are sold to Malaysia, lndonesia, Thailand, Nigeria, Ecuador, Colombia, Paraguay, and many other countries and regions.To produce machines with the best quality and simple operation and with the best price is the aim for Meto Machinery to strive for.

ENTERPRISE STRENGTH

We are a bottle blowing machine manufacturer. We are committed to offering customized solutions for the market and customers, whether individual products or complete sets of equipment. Although the market, application, and customers are different, we have a unique concept to guide the success of customers.

- We will respond patiently and carefully to any consultation and feedback from customers.

- For any inquiry from customers, we will give you a professional and reasonable quotation.

- For any new products of our customers, we will communicate with our customers very professionally, listen to the opinions of our customers and give useful suggestions to ensure the quality of our products.

- After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

- After the commissioning, we will package the equipment by standard export package for shipment.

- According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

- Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Product Features

- Stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

- Less than 0.2% scrap rate for finished bottle.

Bottle blowing machine video

Helpline and Support

008613757660057