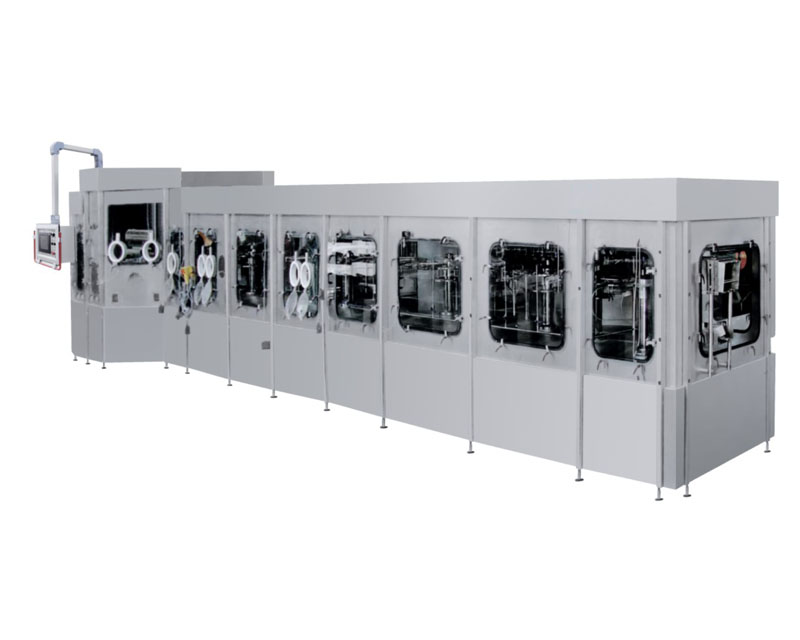

Aseptic processing lines , Isolated Filling Machine

Aseptic processing lines , Isolated Filling Machine

2024/3/24 14:19:44 , visitsPET cold aseptic filling line

Recently, Meto has launched new high speed PET cold aseptic filling line, its capacity is 36000bph. We prepare to develop 48000bph packaging line soon.

Through the development and optimization for isolation and sealing, microbiology control and inspection, cleaning and sterilization, filling, system control, air purifying technology, the Meto cold aseptic filling technology could meet the customer demand for neutral beverage filling, such as coffee, beverage with milk and herbal tea, etc. It provides the consumer a real nature green food without any preservatives and additives.

The assembly line is highly automated with a stable performance. With the high performance price ratio, the locally supplied machines and service are the better choice of the leading and developing beverage companies in pursuit of high-quality products.

Feature

Production to be filled:

Juice, coffee and tea ( herbal tea, green tea and Oolong tea)

Coffee and tea with milk

The way to be filled: cold aseptic filling (at normal temperature)

Container: 280~500mL PET round bottle and square bottle, Φ28mm PCO cap

Production capacity: 460bpm (500mL)

Technical features:

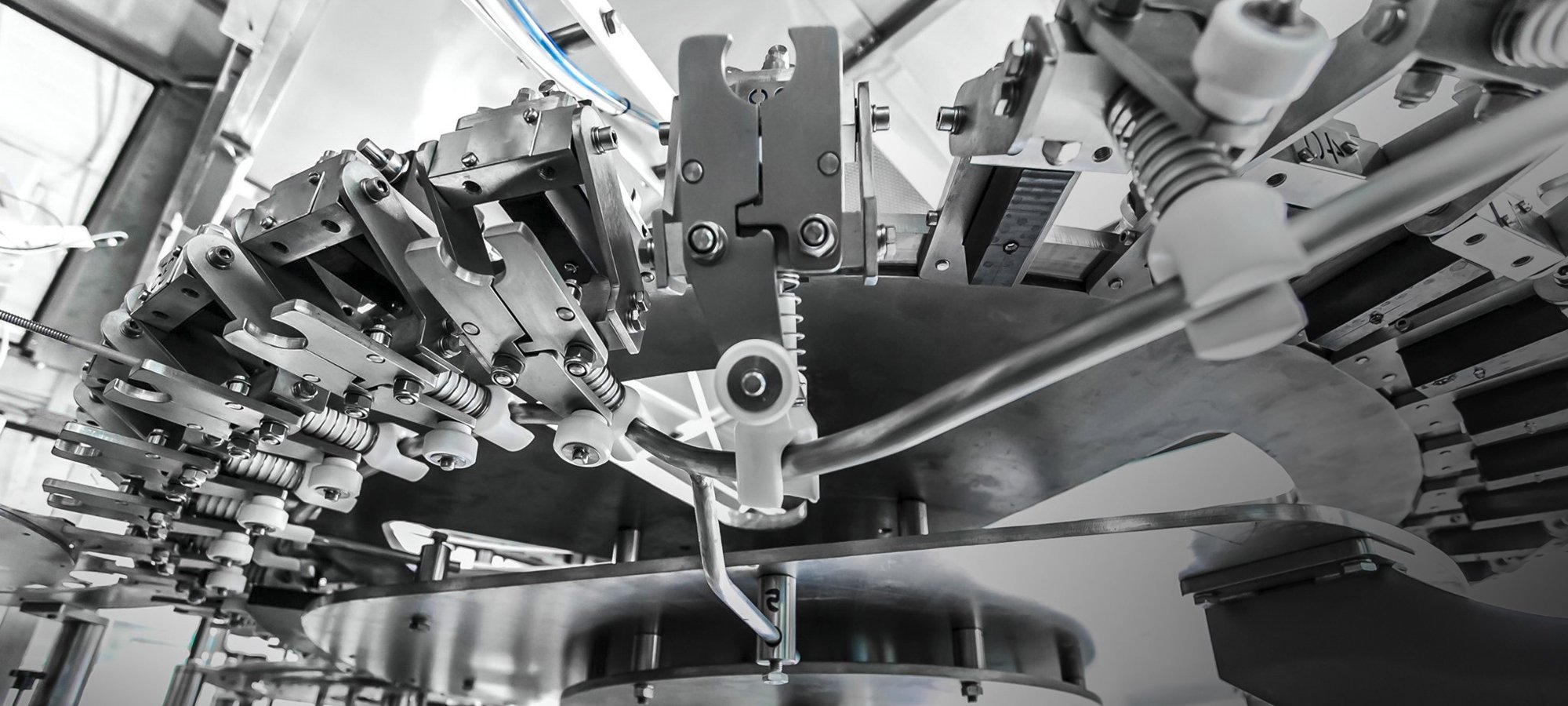

• Multi-Wheeled disinfectant spraying and cleaning technology, to ensure process safety.

• Mechanical or electronic pulsed nozzle, taking into account the reliability and stability and water-saving performance.

• Non-contact filling head, to avoid cross-contamination, ensure microbiological safety.

• Electronic sensor flowmeter volumetric volume, accurate and reliable.

• Aseptic capping machine, self-lubricating ceramic bearings, optional servo motor driven capping machine.

• Disinfectant soak type or on line jetting type cap sterilizer.

• Automatic process detection, control and data report recording system, aseptic monitored to all the key step of production line.

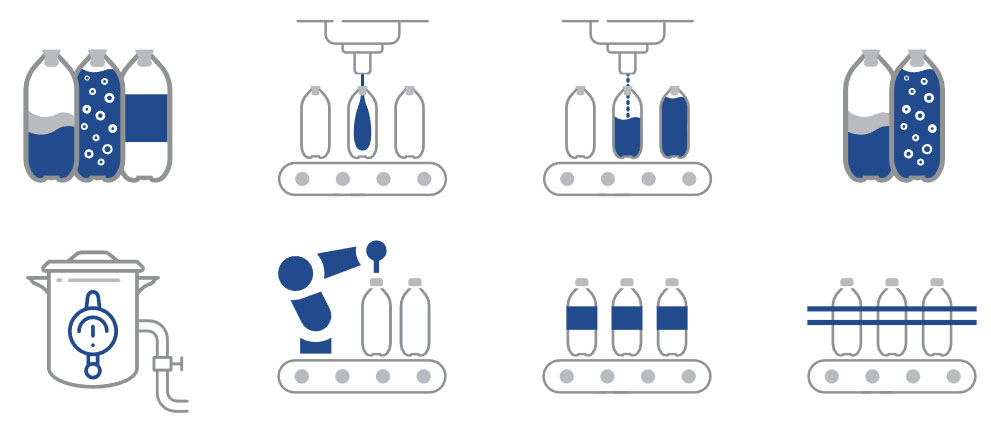

PETaseptic fillingsystem consistsof the followingsubsystems:

• Sterilizing solution blending system

• Empty bottlessterilizationunit

• Caps sterilization unit

• SterilematerialsUHTsterilizationmachine

• Sterilematerial storageandconstant pressure system

• Sterile water UHTsterilizationmachine

• Sterilecompressed air/nitrogen preparation

• CIP/SIP system

• Sterileisolation system

• 百Cleanroom

• COP/SOP Sterile areaCOP/SOP

• Exhaust gas treatment system

• Liquid sealsystem

• Puresteam generator

• Liquid nitrogen addingsystem

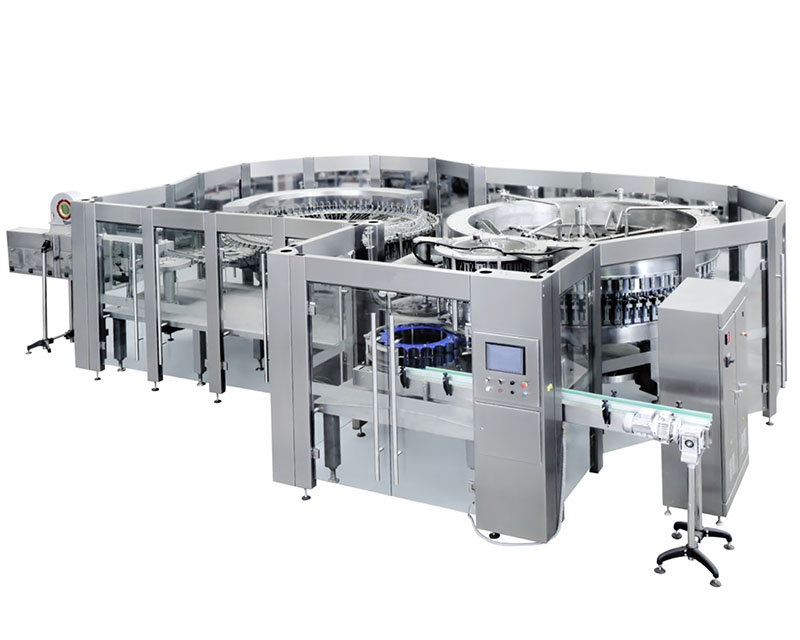

• Aseptic 5 in 1 filling machine

• Entire lineautomatic control system

• Technical parameters monitoring and recording system

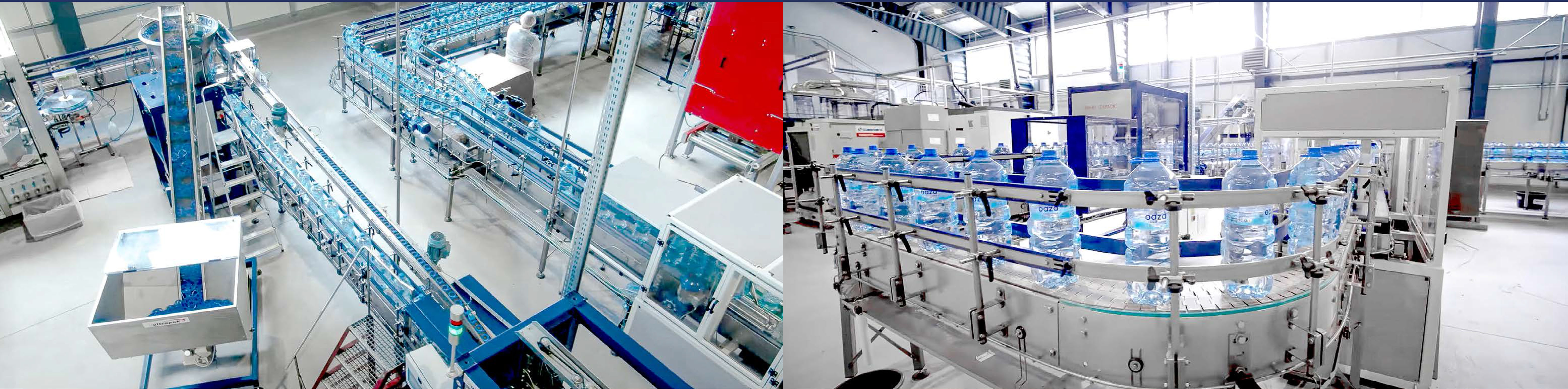

At Met we offer solutions for producing high quality bottled water with a minimal environmental and cost impact. Sustainable bottled water production requires the utmost attention to hygienic conditions and product quality, as well as optimisation of production output to achieve maximum appeal at minimum cost.

For bottled water, appealing bottle design and product quality are key factors to win on the shelves, as consumers demand unique bottle shapes with a premium feel and look that exceeds the quality of tap water. At the same time, bottle lightweighting is needed to reduce the environmental impact and cost of bottling operations. Our bottle design expertise helps to find the RightWEIGHT™ balance between appeal and material use. We are committed to offering our expertise and services to improve and support your water line performance.

Every food and beverage production needs to accommodate diverse capacity and flexibility requirements. Whether you're entering new product categories, seeking increased flexibility or aiming to ramp up production, our diverse selection of filling machines for aseptic, chilled, and food production provides flexible and cost-effective solutions, ensuring your business remains agile and efficient.

Automatic filling machine

Linear Filling machine MP 6-2.B.L.02 is designed for water filling and suitable for PET bottles with the volume up to 10L. Working speed of this filler is 1000 bph of 5L. This machine is built of two modules – for water filling (with four filling nozzles) and capping (with one capping head).

- COMPLETE FILLING LINES Complete filling lines for various food and chemical products, production lines for PET containers from preforms.

- BLOW MOLDING MACHINES Linear and rotative blow moulding machines for the production of PET containers from preforms.

- FILLING MACHINES Linear and rotative machines (RFC, FC) for washing, filling, capping glass and PET containers.

- MIXERS AND SATURATORS Machines for the preparation of carbonated water and fizzy drinks with capacities up to 30,000 l/h.

- SYRUP FILLING LINES Syrope rooms, pasteurizers, soft drinks and juice preparation, tanks, CIP for filling lines, individual projects and turnkey implementations.

- PACKING AND PALLETIZING Packing machines for film, cardboard and WRAP - AROUND.

- LABELLING Linear and rotative devices for paper and polpropylene labels.

- CONVEYORS Internal transport systems, conveyor systems and automation of production lines transfer.

What is more, we pride ourselves in creating eco-friendly PET technology. Our standard PET bottle machine, or as others call it – PET blow moulding machine, PET blow molding machine, PET blow machine or blowing machine – can be easily fitted with which makes energy saving so much easier. Contact us and we will help you choose all the equipment needed for you to start working on your new complete filling line.

Helpline and Support

008613757660057