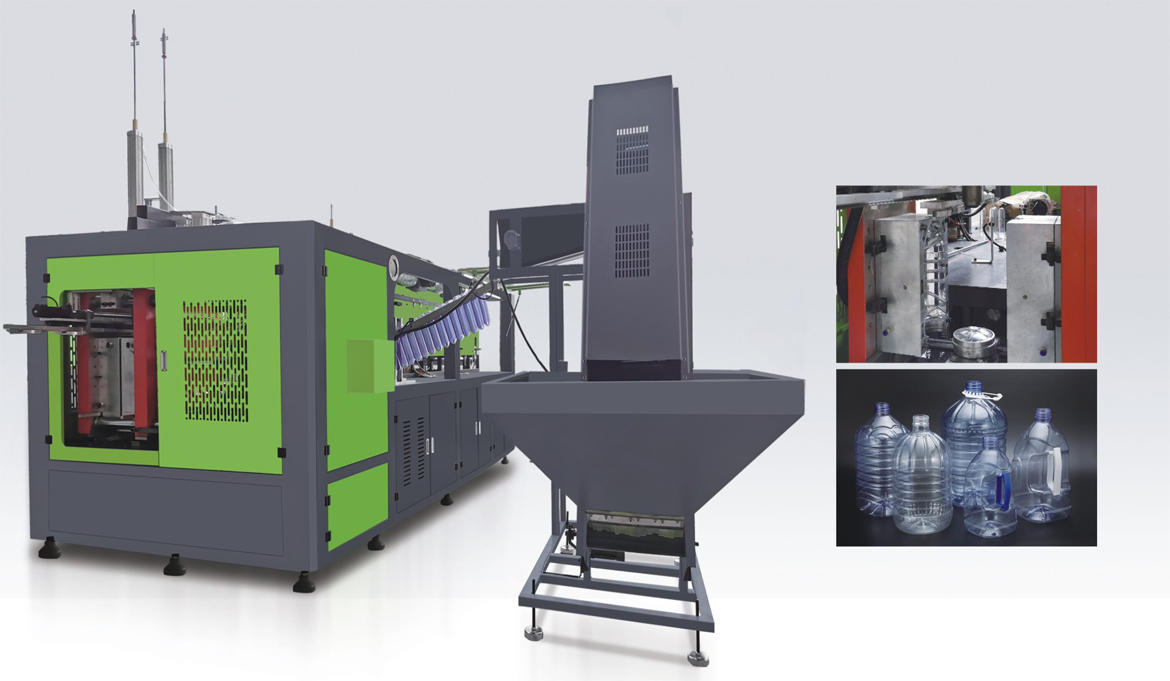

10L Fully Automatic Blow Molding Machine with CE Certificate with Servo

10L Fully Automatic Blow Molding Machine with CE Certificate with Servo

What are our blow molding machines suitable for?

330-2000ml plastic oil bottle

3L-5.5L plastic oil drum bottle

10L-20L large barrel oil barrel bottle

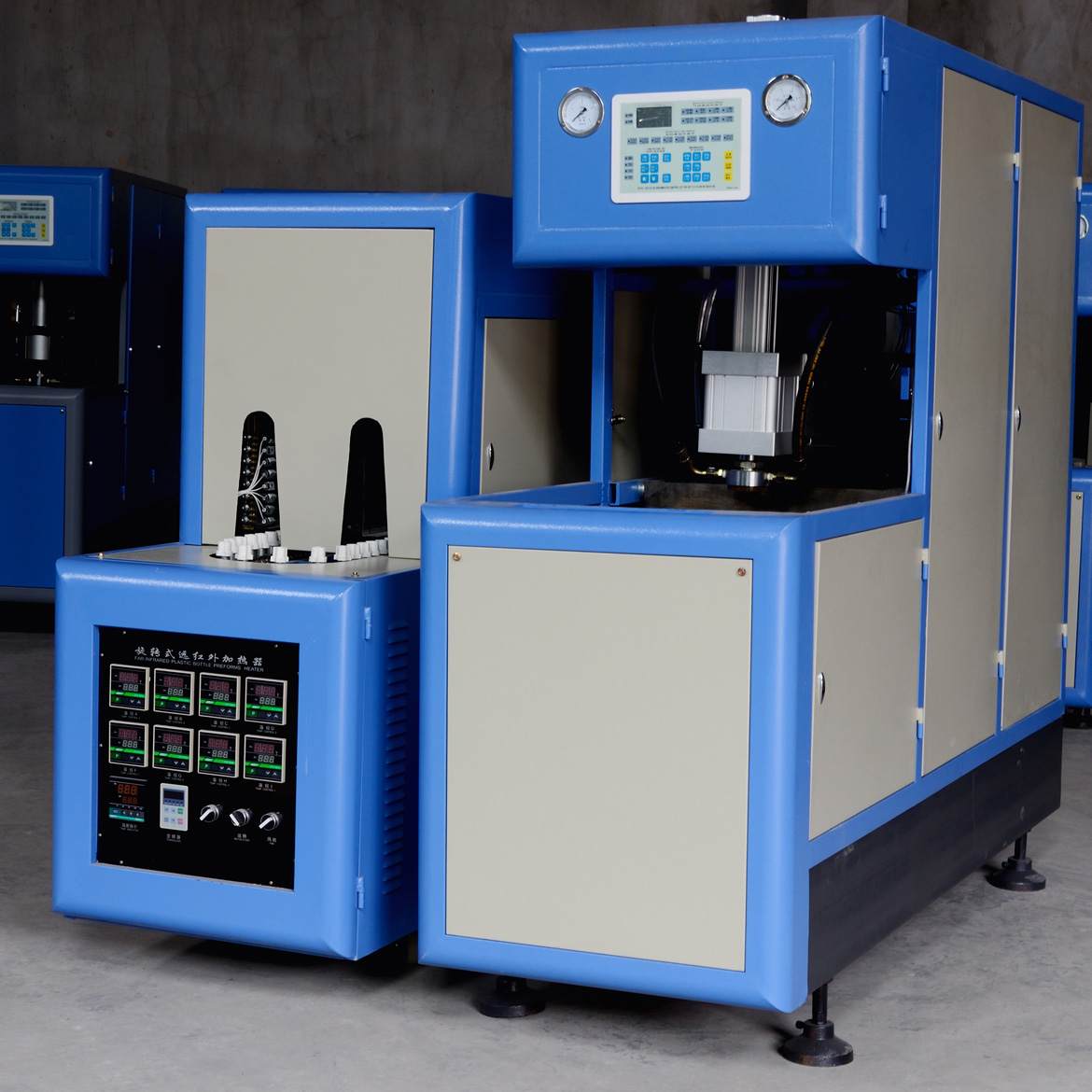

blow molding machine to make big PET bottles from 5L to 10L, semi-automatic and compact machine, low investment and high output.

1.High quality compact machine Most popular pet bottle blowing machine 2000C With touch screen, Use Festo ( German brand) , SMC (Japan brand ) & Parker ( U.S.A Brand) pneumatic components. PLC use Mitsubishi (Japan brand)

2.Nontoxic conveyor belt to carry preforms

3.Produce PET Bottles ( such as: wine, beverage, soybean, vinegar bottles and so on)

4. Easy to maintain

5. Infrared lamps

6.High safety. high speed with high efficiency.

7.Manual saving, one man is enough for operation the machine.

8.Stable performing with easy maintaining.

9.Imported PLC controlling and man-machine interface computer.

10.Japan Omron inspection sensor.

11.Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

12.Power saving design that can increase your profits.

13.Segregate type air controlling system, which is designed for avoiding waste pollution.

Technical Parameters:

MT-A10L-2 |

|||

Molding |

Clamping Force kg |

32000 |

|

Clamping Stroke mm |

260 |

||

Stretching strok mm |

450 |

||

Bottom Stroke mm |

50/70 |

||

Cavity Spacing mm |

250 |

||

Number of Cavity Cavities |

2 |

||

Carriage Unit pcs |

63 |

||

Theoretical Output |

bph |

800-1200 |

|

Electrical System |

Total Power kw |

78 |

|

Heating Power kw |

48x1.5KW=72 |

||

Number of Lamp Layers Layers |

12 |

||

Air System |

Operating Pressure kg/cm² |

7-9 |

|

Low Pressure Air Consumpt Itr/min |

3000 |

||

Blowing Pressure kg/cm² |

30-40 |

||

High Pressure Air Consumpt Itr/min |

6000 |

||

Chiller |

Operating Pressure kg/cm² |

2-4 |

|

Temperature Range ℃ |

10-12 |

||

Consumption kcal/hr |

3000 |

||

Flow Rate Itr/min |

500 |

||

Main Machine |

Main machine dimensions mm(L*W*H) |

4200 x2150x2200 |

|

Main Machine Weight kg |

4500 |

||

Preform Loader |

Preform Loader Dimensions mm(L*W*H) |

2200 x1350x2650 |

|

Preform Loader Weight kg |

550 |

||

Whole plant equipment for beverages. Professional and one-stop solution tailored to your beverage production and packing requirement: from PET bottle blow molding to water treatment, bottling and packing

We are committed to serve our presitigious customers with the best quality molding machines. By providing these machines in customized specifications, we have emerged as a preferred choice of most of the clients. Rely on us and place orders now This is one of the superior quality Blow Molding Machine in the indusry.

We ensure to provide machines with best technical specification. Not just this, Blow Molding Machine provided by us is also available market competitive prices.

Helpline and Support

008613757660057