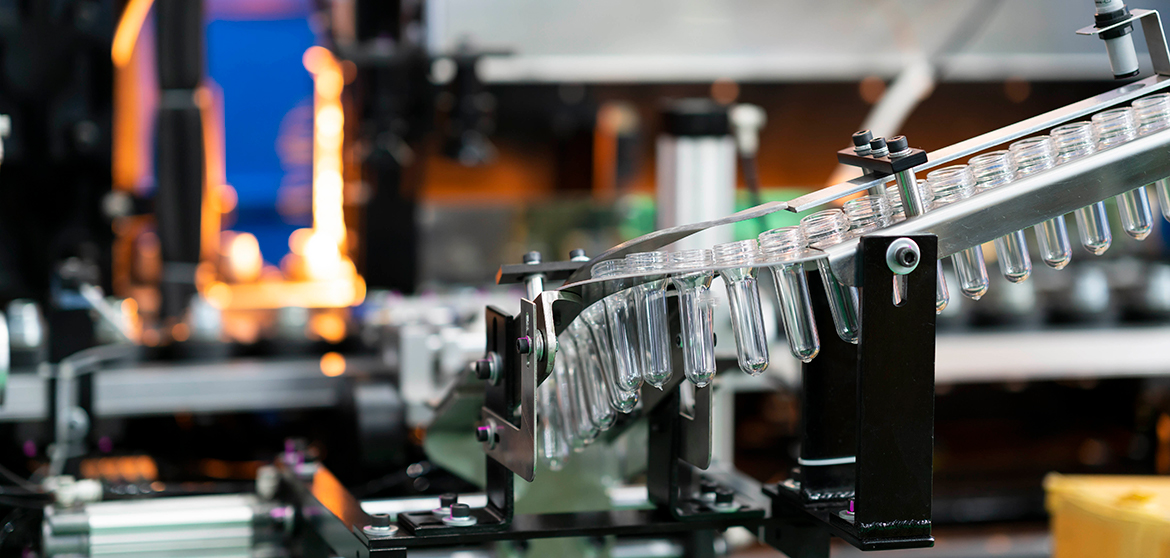

Common problems in the production process of fully automatic bottle blowing machine

Common problems in the production process of fully automatic bottle blowing machine

1.How to operate the bottle blowing machine?

The bottle blowing machine is very easy to operate. It has an operating instruction. It is clearly that how to operate the bottle blowing machine in operating instruction. The bottle blowing machine can be easily used according to the operating instruction. Of course, you can contact us when you have any questions, we will help you solve it in time.

2.

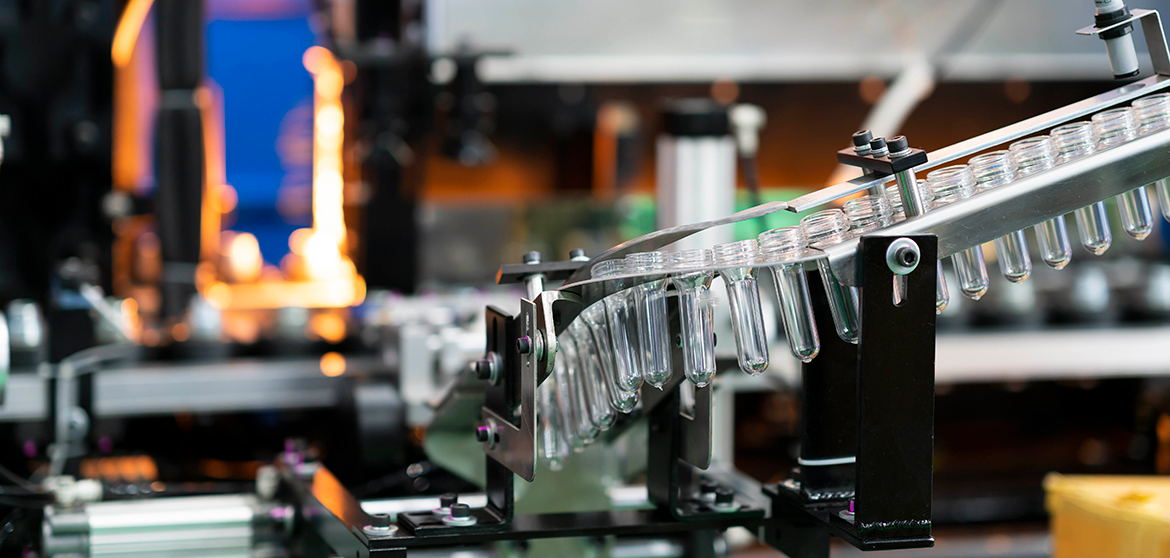

It is necessary that the bottle blowing machine needs scheduled maintenance. Especially, water system and air system in the machine, It should be noted that once there is a problem with the water system and the air system, you should stop using it immediately. Of course, environmental factors should also be considered, a few days ago there was a mineral water canning factory located at the foot of the mountain, due to the production environment is relatively humid, the machine has never been maintained, resulting in rust in the chain of the machine so that the machine can not produce.

3.

There are two reasons for the deformation of bottles produced by the bottle blowing machine: bottle mouth deformation and bottle body deformation.

Bottle mouth deformation: The preform bottle is moved through the transmission chain and the heating tube makes the temperature of the preform bottle constantly rise. The transmission chain is used in circulation. The temperature of the transmission chain is high after continuous heating. As a result, the temperature of the bottle mouth will be higher than that of the bottle body when the preform bottle passes through the heating tube, and the bottle mouth will be deformed. At this time, the temperature of the bottle mouth can be reduced by increasing the cold air or cold water at the mouth of the bottle.

Bottle deformation: The common reason for bottle deformation is that the tension rod is not adjusted properly. It is recommended that the stretch ratio between the preform bottle and the bottle body is 1:2.5 (excluding the bottle mouth), and the heating temperature is adjusted to extend the blowing time.

Helpline and Support

008613757660057