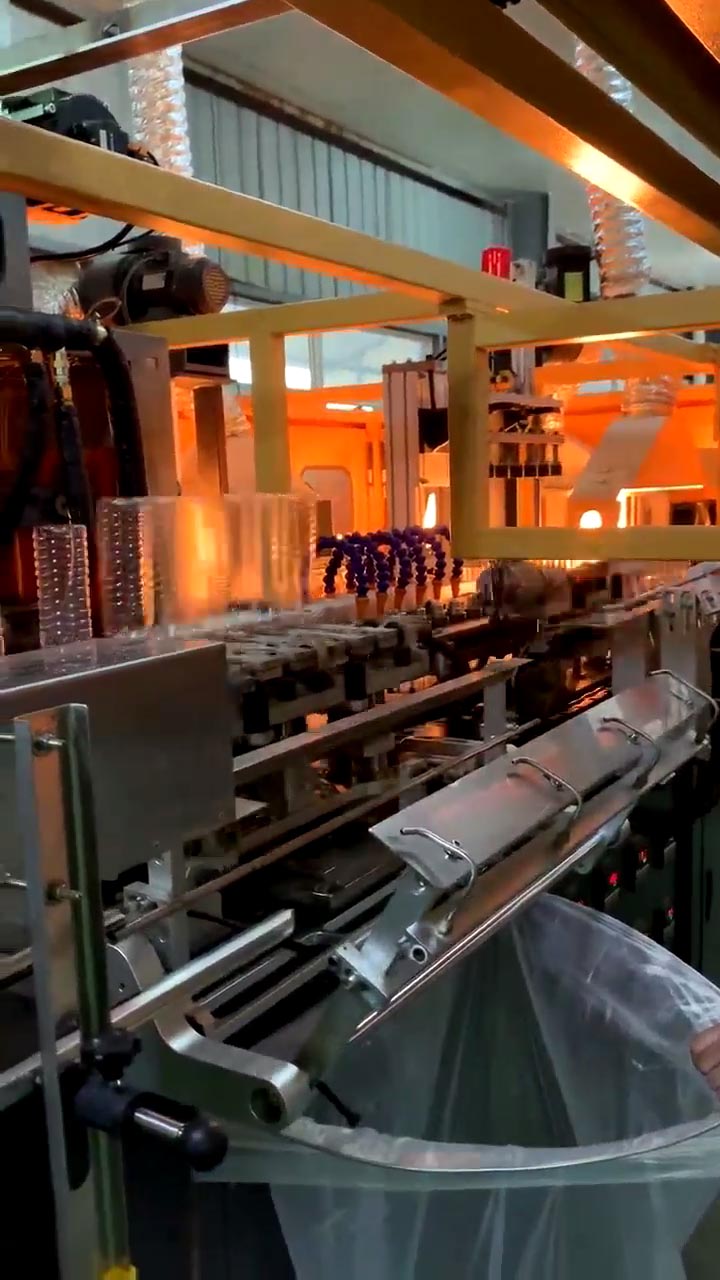

3L 2 cavity semi-automatic bottle blowing machine

3L 2 cavity semi-automatic bottle blowing machine

2024/3/29 , visits1. Produce bottle from 0.1L to 3L

2. Output capacity up to 900 for 0.6L using two-cavity blow mold

3. Advanced PLC control system with a use-friendly panel and time-control precision of PLC up to 0.01second

4. Equipped with special designed air storage unit

5. Using Infrared preform heater

6. Independent Temperature Control for different heating lamp to get ideal preform heating results

7. Heating lamps are adjustable in directions to suit various preforms.

8. Operated only by one person without special training.

9. Simple installation & startup adjustment. 10. Waste rate of finished bottle is less than 0.2%.

| ITEM | 3L 2 cavity semi-automatic bottle blowing machine |

| Clamping force | 13T |

| Clamping stroke | 330mm |

| Max.stretching stroke | 440mm |

| Number of cavities | 0.1-3L 2cavity |

| Theoretical output | 0.5-2.5L:800-1500bph |

| Max.mould thickness | 280mm |

| Mould plate size | 490x470mm |

| Voltage standard | 380v/3PH/50Hzorspecoal order |

| Total power(full loaded) | 3-10KW 5-15KW |

| Min.air compressor | 1.2mm3/min3.0Mpa |

| Blow molding machine | 175x60x180cm |

| Pre - heater | 150x70x140cm |

| Net weight | 0.75T |

| Container volume | 0.5-2.5L |

| Neck diameter range | 28-100mm |

| Container diameter | 150mm |

| Container height | 450mm |

Bottle blowing machine video

-

Ruby

Ruby  +86 13757660057

+86 13757660057 meto@kemomachine.com

meto@kemomachine.com +86 13757660057

+86 13757660057 aaa

aaa Scan, Add Friends

Scan, Add Friends

Helpline and Support

008613757660057

Get A Free Consultation