Carbonated Beverage Filling Machine & CSD Filler

Carbonated Beverage Filling Machine & CSD Filler

2024/3/24 , visitsWide production capacity range: 2000BPH-36000BPH CSD filler.

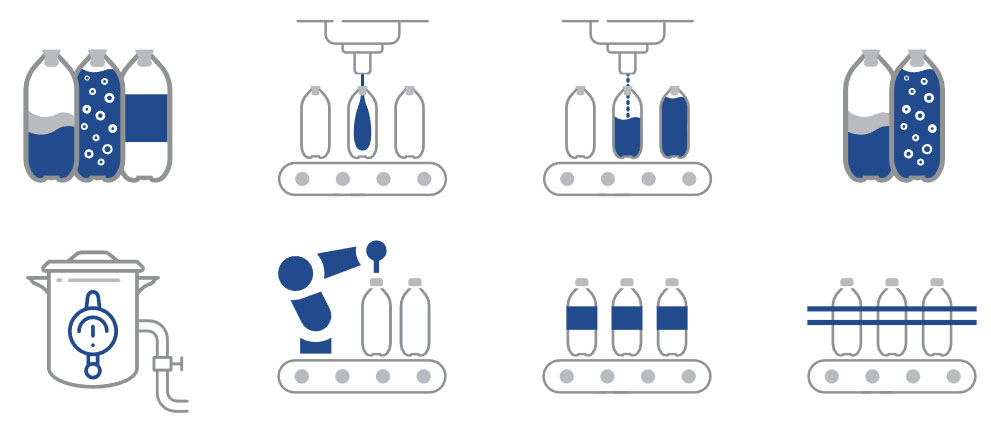

Different CSD filling technology: Cold drink filling and CSD ambient filling.

Less energy consumption and less area needed.

Many customers have purchased CSD filler to fill their own carbonated soft drink. But the problem is that the production efficiency of their machines are less than 60%. After years of updating iterative filling process, METO has successfully solved the problem of low efficiency of CSD filling machine, and the whole machine can achieve 99% production efficiency.

Are you planning to start a carbonated soft drink production business? If Yes, then you must be considering getting some important machinery needed to run the production line.

One of such important machinery needed is the carbonated soft drink filling machine (CSD filling machine). However, it is important to purchase your CSD filling machines from a reliable carbonated soft drink filling machine manufacturer.

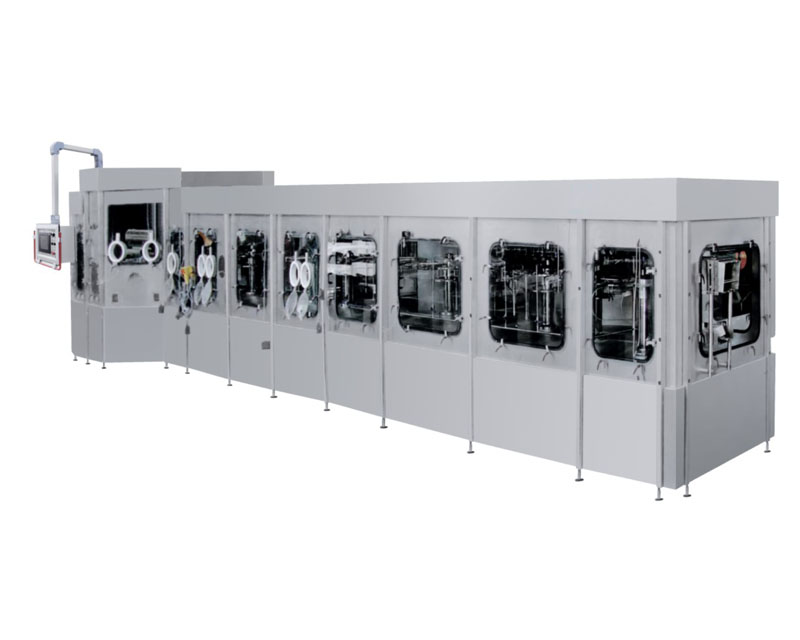

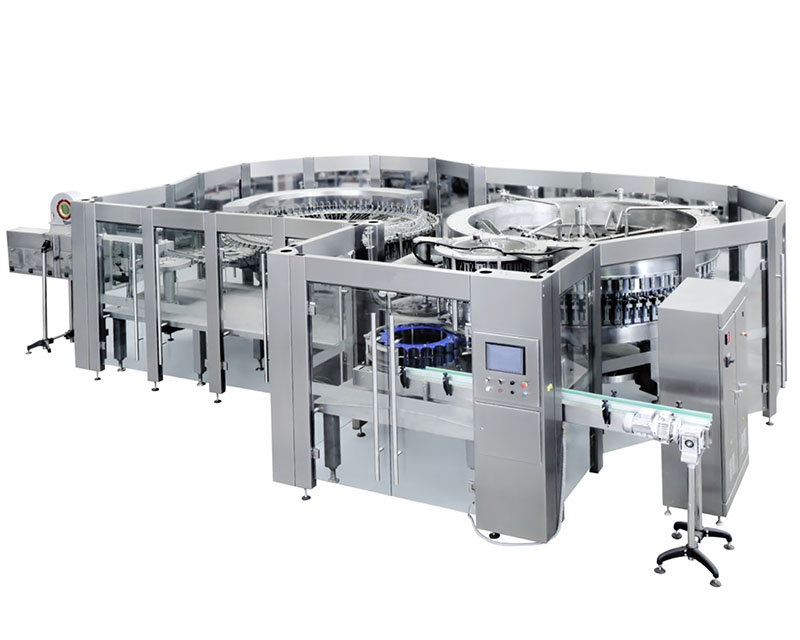

This machine is one cost-effective machine suitable for washing, filling and sealing bottled carbonated soft drinks.It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling repose fully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system.

Main features :

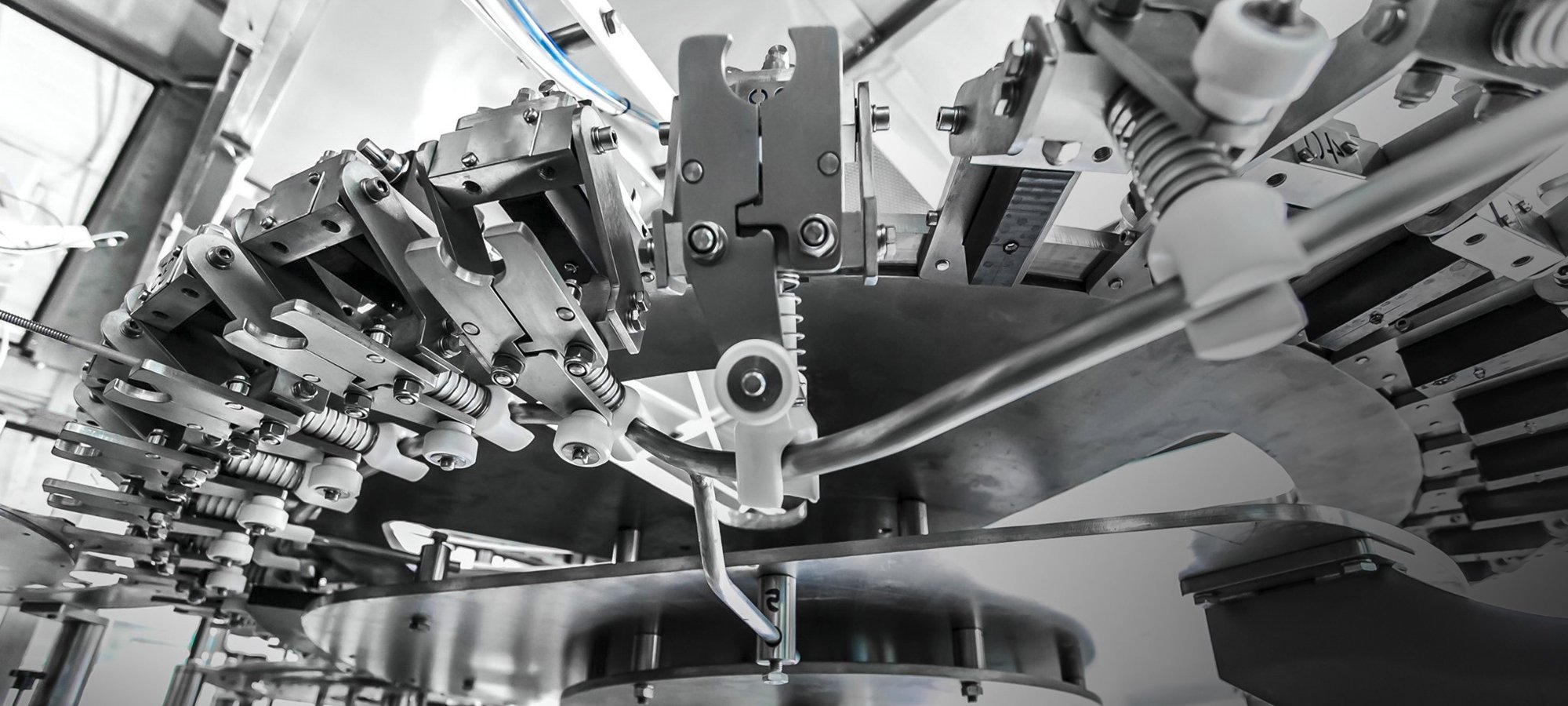

1.Washing Part

All 304 stainless steel rinser heads, water spray style inject design, more save water consumption & more clean, 304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing, 304 stainless steel washing pumps

2.Filling part

Isobaric filling , & filling smoothly & steadily

The centering oriented adopts guide rod with special bottle neck holding

Filling temperature:0~4℃

All 316 stainless steel contact parts & liquid tank, fine polish, easy to clean

3. Capping part:

Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

All 304 stainless steel construction

No bottle no capping and Automatic stop when lack of bottle

| Project Name: Carbonated Soft Drink Filling Machine | ||||||||

| Model | METO 24-24-8 | |||||||

| Washing Nos | 24 | |||||||

| Filling Nos | 24 | |||||||

| Capping Nos | 8 | |||||||

| Capacity(BPH) | 8000 | |||||||

| Suitable bottle and cap | PET circular or square with screw cap | |||||||

| Bottle Volume | 150ml to 2.5Ltr (Customized) | |||||||

| Bottle diameter(mm) | Dia50-Dia115mm | |||||||

| Bottle heighter | 160-320mm | |||||||

| Compress air pressure(Mpa) | 0.3-0.4Mpa | |||||||

| Washing medium | Aspetic water | |||||||

| Rinsing pressure(Mpa) | >0.06Mpa<0.2Mpa | |||||||

| Filling temperature | 0~4℃ | |||||||

| Filling theory | Isobaric filling | |||||||

| Total powder3 | 3KW | |||||||

| Dimension (meter) | 2.88*2.18*2.65M | |||||||

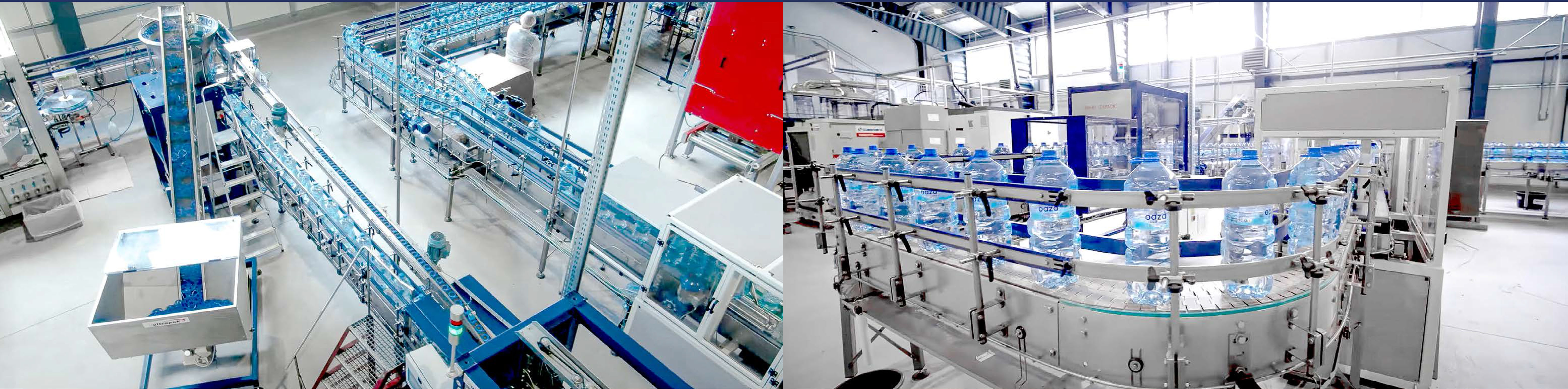

At Met we offer solutions for producing high quality bottled water with a minimal environmental and cost impact. Sustainable bottled water production requires the utmost attention to hygienic conditions and product quality, as well as optimisation of production output to achieve maximum appeal at minimum cost.

For bottled water, appealing bottle design and product quality are key factors to win on the shelves, as consumers demand unique bottle shapes with a premium feel and look that exceeds the quality of tap water. At the same time, bottle lightweighting is needed to reduce the environmental impact and cost of bottling operations. Our bottle design expertise helps to find the RightWEIGHT™ balance between appeal and material use. We are committed to offering our expertise and services to improve and support your water line performance.

Every food and beverage production needs to accommodate diverse capacity and flexibility requirements. Whether you're entering new product categories, seeking increased flexibility or aiming to ramp up production, our diverse selection of filling machines for aseptic, chilled, and food production provides flexible and cost-effective solutions, ensuring your business remains agile and efficient.

Automatic filling machine

Linear Filling machine MP 6-2.B.L.02 is designed for water filling and suitable for PET bottles with the volume up to 10L. Working speed of this filler is 1000 bph of 5L. This machine is built of two modules – for water filling (with four filling nozzles) and capping (with one capping head).

- COMPLETE FILLING LINES Complete filling lines for various food and chemical products, production lines for PET containers from preforms.

- BLOW MOLDING MACHINES Linear and rotative blow moulding machines for the production of PET containers from preforms.

- FILLING MACHINES Linear and rotative machines (RFC, FC) for washing, filling, capping glass and PET containers.

- MIXERS AND SATURATORS Machines for the preparation of carbonated water and fizzy drinks with capacities up to 30,000 l/h.

- SYRUP FILLING LINES Syrope rooms, pasteurizers, soft drinks and juice preparation, tanks, CIP for filling lines, individual projects and turnkey implementations.

- PACKING AND PALLETIZING Packing machines for film, cardboard and WRAP - AROUND.

- LABELLING Linear and rotative devices for paper and polpropylene labels.

- CONVEYORS Internal transport systems, conveyor systems and automation of production lines transfer.

What is more, we pride ourselves in creating eco-friendly PET technology. Our standard PET bottle machine, or as others call it – PET blow moulding machine, PET blow molding machine, PET blow machine or blowing machine – can be easily fitted with which makes energy saving so much easier. Contact us and we will help you choose all the equipment needed for you to start working on your new complete filling line.

Helpline and Support

008613757660057