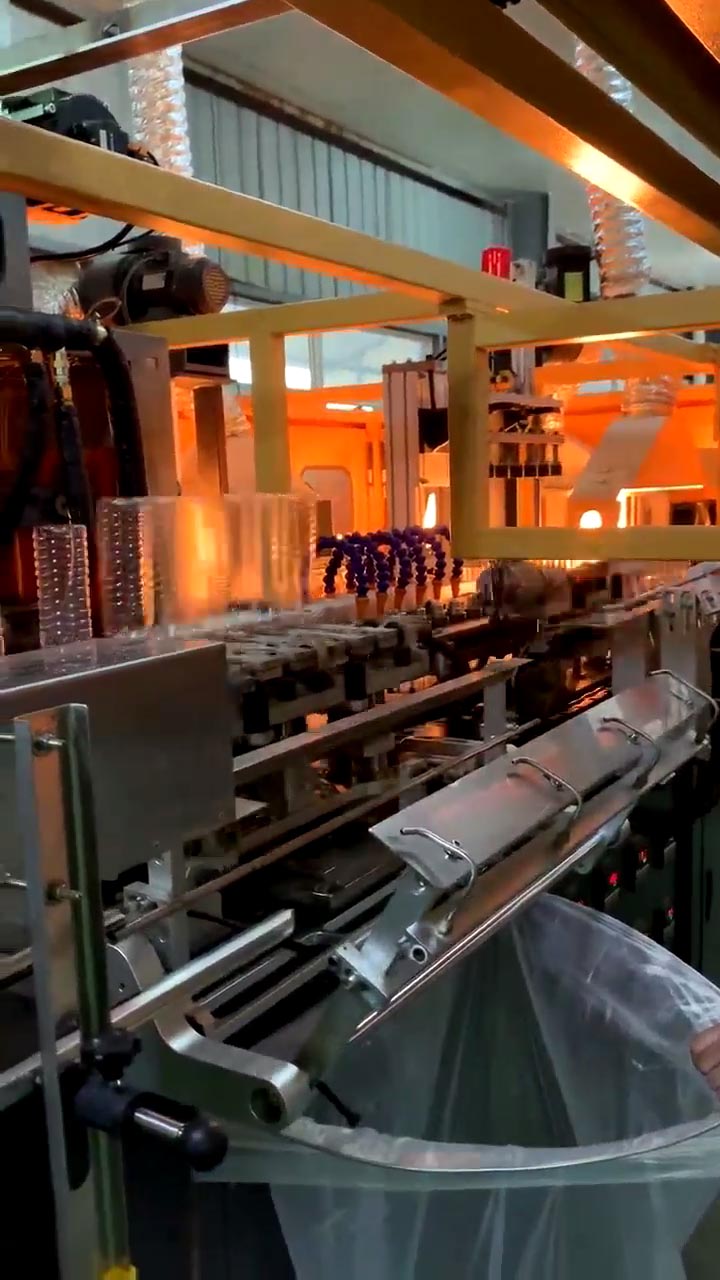

3-Cavity 1.5L Stretch water Blow Moulding Machine for Pet Bottle Manufacturing

3-Cavity 1.5L Stretch water Blow Moulding Machine for Pet Bottle Manufacturing

2024/3/28 , visitsPET blowing machine for 2l linear bottle blowing machines are used in the production of PET water bottles, hot filling bottles, carbonated beverage bottles, edible oil bottles, and pesticide bottles.

Meto Machinery's linear bottle blowing machine stretches preforms by using a servo motor-controlled stretch rod. The advantage is that it can be stretched in sections,and positioning of the preform is at first in order to ensure the verticality of the preforms during stretching, then secondary stretching.

Ensure the uniformity and consistency of each preform stretching.At the same time,bottle blowing machine has a fast stretching speed and precise position.

Sufficient InventoryWith a standardized workshop covering a total area of 20,000 square meters, we maintain ample spare parts inventory for timely delivery.All equipment undergoes a 24-hour test run before leaving the factory to ensure mechanical components stability.

Professional TrainingProfessional installation team will visit your factory to install the machines and train your staff . Additionally offer free video training sessions.

High positioning accuracy, fast speed and stability, good reliability. Gas circuit design will divide action and blowing into three parts to meet the needs of different pressure for blowing bottles and movement; Adopt high pressure and double crank arm link locking, strong clamping force.

Adopt infrared lamp heating

Adopt infrared lamp heating, strong penetration, preform rotation heating, track revolution, heating evenly, fast and reliable; Heating lamp, reflector width and height can be adjusted to suit preform heating of different structure, with automatic temperature-removal device to ensure the constant temperature of oven.

Auto-loader

Auto-loader improves working efficiency, accurate transportation, reliable and durable, raw materials are completely free of moisture, pollution, foreign matter, and loss during feeding process. Realize transportation process of feeding process, avoid danger of high-altitude feeding, reduce labor intensity and increase production efficiency.

Intelligent Human-Machine Interface

1.Human-machine interface control, easy operate and monitor.

2.Live production information supervise, auto record production data everyday

3.Failure warning and troubleshooting.

| Item |

MT-6000 | |

| Bottle type specification | Cavity | 4 |

| Theory output | 6000 bph | |

| Max.volume | 2L | |

| Bottle mouth maximum overall diameter | 28-38mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximum height | 330mm | |

| Power specification | Light tube quantity | 40pcs |

| Light tube power | 1.5KW | |

| Maximum heating power | 60KW | |

| All electric machine installation | 91KW | |

| Actual consumption | 70KW | |

| Air pressure specification | Work pressure | 7-9kg/c㎡ |

| Low-pressure gas consumption | 1600L/min | |

| Blow bottle pressure | 25-35kg/c㎡ | |

| Higher -pressure gas consumption | 6000Ltr/min | |

| Air pressure specification |

Work pressure | 5-6 kg/c㎡ |

| Temperature range | 10℃ | |

| Consumption | 8000kcal/hr | |

| Frozen water flow | 138L/min | |

| Machine specification | Machine size | 4.05x2.16x2.45 |

| Machine weight | 4.3ton | |

Bottle blowing machine video

-

Ruby

Ruby  +86 13757660057

+86 13757660057 meto@kemomachine.com

meto@kemomachine.com +86 13757660057

+86 13757660057 aaa

aaa Scan, Add Friends

Scan, Add Friends

Helpline and Support

008613757660057

Get A Free Consultation