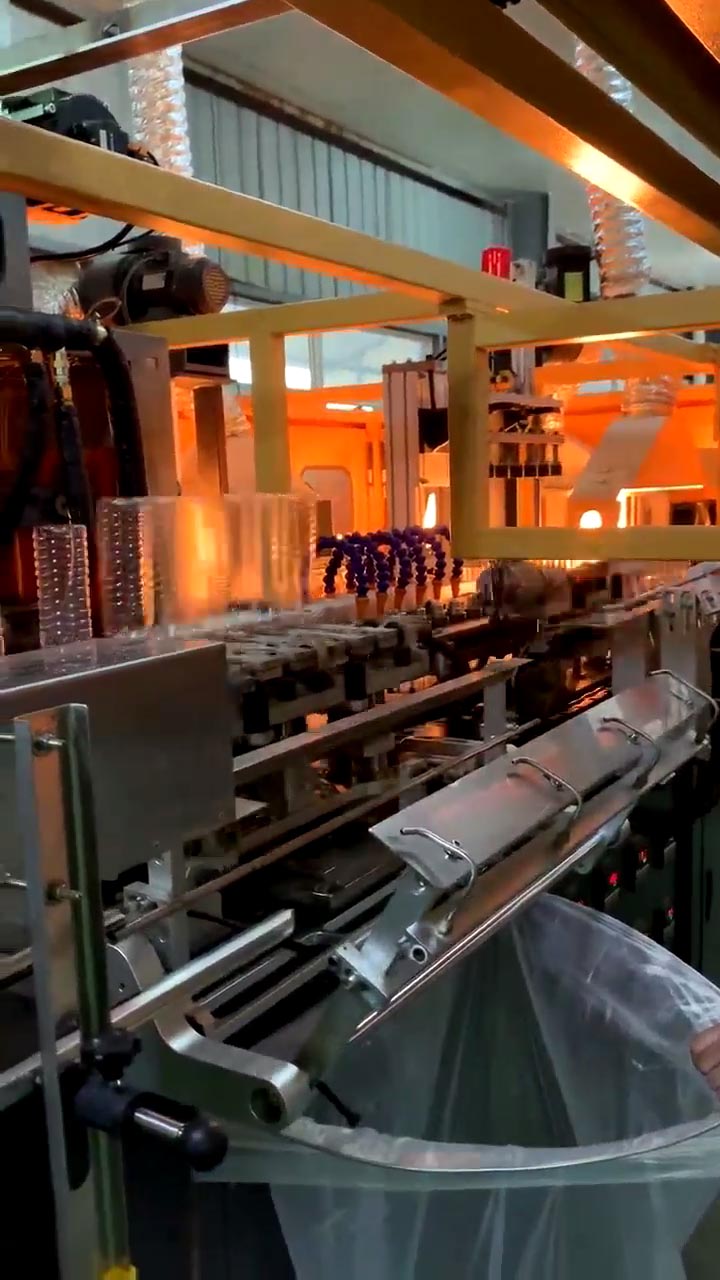

330ml 750ml 1500ml Fully Automatic Plastic Small Pet Stretch Plastic ice Mineral Water Bottle Blow Molding Machine

330ml 750ml 1500ml Fully Automatic Plastic Small Pet Stretch Plastic ice Mineral Water Bottle Blow Molding Machine

2024/9/29 9:14:47 , visitsMachine Featuers------Bottle molding machine

1. Utilization of automatic central lubrication.

2. Compact space design for convenience of mold-conversion,repairing and maintenance.

3. Minimized transfer pitch for increasing heating efficiency and saving energy.

4. Swift exchange design for preform mandrels.

5. Optimized air flow in the oven for stable heating process.

6. Easy to adjust,exchange and access heating oven;Protection for preform thread against heating.

7. Intact rotating robot grip with linear guider for right access,rapid motion;reducing adjustment and maintenance time.

8. Electronic inspector for ejecting faulty preform and bottles.

9. Fast,safe,and accurate cam-controlled blowing wheel for providing the best bottles.

10. Precise control of blowing technique to produce less-weighted bottle.

11. Smart design for quick conversion of blow mold.

12. Through finite element analysis to optimize modular design for reducing machine wearing and moving inertia.

13. Operating machine through touch panel; program protected by code lock

Fast Delivery High Speed Automatic Pet Plastic Stretch biodegradable bottle blowing machine for cold water bottle 1L 2L 4L 5L | ||||

Technical Parameters | Main Parts & Brand | |||

ITEM | MT-300S | Parts / Name | Brand | |

Theoretical output | 3000 | Stretch sealing system | Factory self made | |

Max.container volume | 1.5L | Mold base drive system | Japan CKD/SMC | |

Max.neck diameter | 45MM | Displacement system | servo engine | |

Max.container diameter | 120MM | Pneumatic auxiliary system | Japan CKD/SMC | |

Max.container height | 350MM | Automatic feeding system | Germany FESTO | |

Number of cavity | 3 | Driving motors system | Japan OM | |

Number of lamp | 20kw | Electric controller | Japan Mitsubishi | |

Actual power consumption | 12KW | Prefomm detection | Japan Omron | |

Operatating low pressure | 0.7-1.0Mpa | Blowing valve sets | Blowing & exhaust combined valve | |

Blowing pressure | 2.5-3.5Mpa | Location component | F actory self made | |

Operating pressure | 0.3-0.5Mpa | Slide guide | Japan THK | |

Machine dimension | 3.55×1.5×2.2 | |||

Machine weight | 2800Kg | |||

Bottle blowing machine video

-

Ruby

Ruby  +86 13757660057

+86 13757660057 meto@kemomachine.com

meto@kemomachine.com +86 13757660057

+86 13757660057 aaa

aaa Scan, Add Friends

Scan, Add Friends

Helpline and Support

008613757660057

Get A Free Consultation