Large Hot Selling MT-A1 8000-12000 BPH Automatic PET small hand washing Bottle Making Machine

Large Hot Selling MT-A1 8000-12000 BPH Automatic PET small hand washing Bottle Making Machine

2024/9/29 9:47:28 , visitsMETO series linear bottle blowing machines are used in the production of PET water bottles, hot filling bottles, carbonated beverage bottles, edible oil bottles, and pesticide bottles.METO series linear bottle blowing machines are used in the production of PET water bottles, hot filling bottles, carbonated beverage bottles, edible oil bottles, and pesticide bottles Machinery's MT series linear bottle blowing machine stretches preforms by using a servo motor-controlled stretch rod. The advantage is that it can be stretched in sections,and positioning of the preform is at first in order to ensure the verticality of the preforms during stretching, then secondary stretching.Ensure the uniformity and consistency of each preform stretching.At the same time,bottle blowing machine has a fast stretching speed and precise position.

MT series linear bottle blowing machine features:

1.stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

3. servo transmission system, high positioning accuracy, fast speed, good stability and reliability.

4. suitable for flexible production of small quantity and various bottle shape,wide range of applications,meet customer needs.

5. increase energy using efficiency,increase productivity per unit of time.

6. manual and automatic methods of operation, human-machine interface control, simple operation.

7. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

8. safety self-locking device in each mechanical action,when a certain process fails, the program will automatically switch to a safe state.

Large Hot Selling MY-A1 8000 BPH Automatic Bottle Making Machine | ||||

Technical Parameters | Main Parts & Brand | |||

ITEM | MT-A1 | Parts / Name | Brand | |

Theoretical output | 12000 | Stretch sealing system | Factory self made | |

Max.container volume | 750ML | Mold base drive system | Japan CKD/SMC | |

Max.neck diameter | 45MM | Displacement system | servo engine | |

Max.container diameter | 72MM | Pneumatic auxiliary system | Japan CKD/SMC | |

Max.container height | 360MM | Automatic feeding system | Germany FESTO | |

Number of cavity | 8 | Driving motors system | Japan OM | |

Number of lamp | 58 | Electric controller | Japan Mitsubishi | |

Actual power consumption | 35KW | Prefomm detection | Japan Omron | |

Blowing pressure | 1.5-2.5Mpa | Blowing valve sets | Blowing & exhaust combined valve | |

Machine size (MM) | 6500x1750x1820 | Location component | F actory self made | |

Machine weight | 4950Kg | Slide guide | Japan THK | |

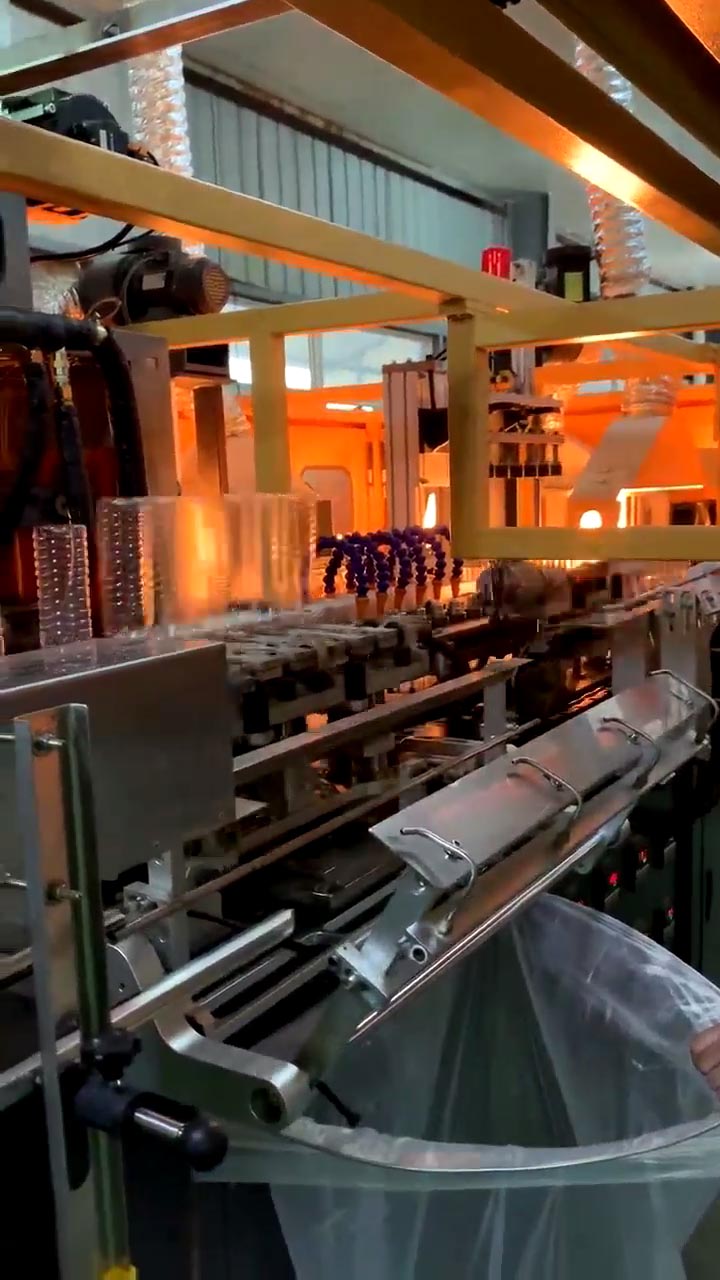

Bottle blowing machine video

-

Ruby

Ruby  +86 13757660057

+86 13757660057 meto@kemomachine.com

meto@kemomachine.com +86 13757660057

+86 13757660057 aaa

aaa Scan, Add Friends

Scan, Add Friends

Helpline and Support

008613757660057

Get A Free Consultation