Carbonated Beverage Bottle

Carbonated Beverage Bottle

2024/3/26 , visitsWe manufacture environmentally friendly carbonated beverage bottle blow molding machines that can efficiently manufacture beverage bottles, mineral water bottles, condiments, etc. according to your needs.

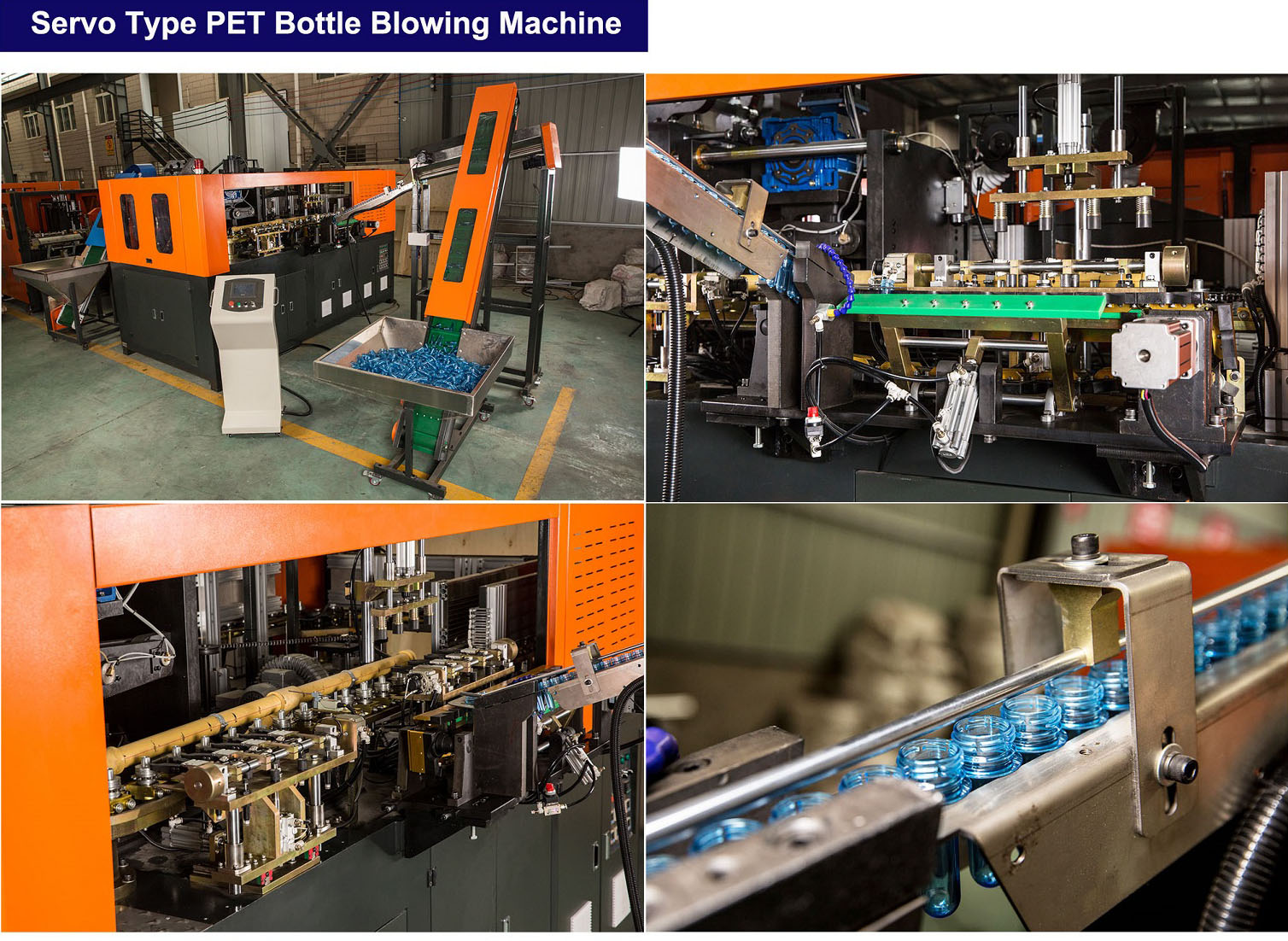

full-automatic high-speed bottle blowing machine is suitable for producing 06-2 liter PET plastic containers and bottles of various shapes. It is widely used in the production of carbonated beverage bottles, mineral water bottles, oil bottles, seasoning bottles, cosmetics, wide-mouth bottles, etc.

330-550ml small Carbonated Beverage bottle,550-750ml Carbonated Beverage bottle,1000-2000ml large Carbonated Beverage bottle

Suitable for all shapes of PET plastic bottles,widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc

6 Cavity Full Automatic Blow Moulding Machine, with production capacity at 6,000~7,000 bottles per hour, is suitable for large water production line

PET blowing machine for 2l linear bottle blowing machines are used in the production of PET water bottles, hot filling bottles, carbonated beverage bottles, edible oil bottles, and pesticide bottles.

| Model | Item | Meto-A2 | Meto-A4 | Meto-A6 |

| Productivity | Depend on bottle design | 1800-2000 PCS/H | 3200-4000 PCS/H | 4000-5500 PCS/H |

|

Product type |

Volume | 0.1-2.0L | ||

| Body diameter |

≤100mm

|

|||

| Height | ≤310mm | |||

| Neck diameter | ≤38mm | |||

| Mold | Cavity | 2 | 4 | 6 |

| Mold thickness | 240mm | |||

| Mold volume | 260*240*370mm | 510*240*360mm | 640*240*360mm | |

| Main Power | Electrical source Power | 380V/220V 50/60HZ | ||

|

|

3Phase

|

|||

| Rated power | 25kw | 49kw | 73kw | |

| Really use power | 6.5kw | 13kw | 25kw | |

| Air system | HP air compressor | 1.6m3/min3.0MPa | 3.0m3/min3.0MPa | 6.0m3/min3.0MPa |

| LP air compressor | 1.0m3/min1.0MPa | 1.6m3/min1.0MPa | 2.0m3/min1.0MPa | |

| Air Tank | 0.6m33.0MPa | 2.0m33.0MPa | 6.0m33.0MPa | |

| Air dryer | 1.0m3/min3.0MPa | 2.0m3/min3.0MPa | 6.0m3/min3.0MPa | |

| Cooling water | Water Chiller | 3HP | 3HP | 5HP |

|

Machine

|

Size(L*W*H) | 1900*1280*1930mm | 1900*1860*1930mm | 4100*1400*1800mm |

| Weight | 2000kg | 3600kg | 3200kg | |

|

Unscrambler

|

Size(L*W*H) | 2000*950*2480mm | ||

| Weight |

250kg

|

|||

SAVE ENERGY :The preform heating and blowing are on separated section, so that it can save the waiting time of each unit. Thepreforms are heated intensively, as the rotary machine heating type, improve the heating eficiency. Meanwhile, the high pressure air cansaved by air recycling system, for the pre-blow or low pressure air supply, save energy.

SAVE SPACE: The infeeding system is inside the machine, the heating structure save the preform pitch distance, save the space

HIGH EFFICIENCY: We improve about 20% output, in the situation of low down the machine energy

INFEEDING SYSTEM: The infeeding system is in single channel with less sensors for better infeeding.

HEATING SYSTEM: Preforms are heated intensively, the cooling device and the cross ventilation protect the preform neck from out ot shape, improve the energy utilization, and heating efficiency

TRANSFER UNIT: The variable pitch device is controlled by servo for stable and accurate transferring

CLAMPING UNIT: The clamping unit is controlled by servo motor to ensure the synchronization, stable running and precise location

HIGH PRESSURE AIR RECYCLE SYSTEM: The high pressure air recycle system save the high pressure to the tank, reduce the noiseand save energy lost.

URL of this article: https://www.metomachinery.com/Application/Carbonated-Beverage-Bottle.html

Bottle blowing machine video

Helpline and Support

008613757660057