Drinking Water Bottle

Drinking Water Bottle

2024/3/26 , visitsWhat purified water bottles are suitable for our blow molding machine?

330-550ml small bottle of mineral water bottle 550-750ml mineral water bottle 1000-2000ml large bottle of mineral water bottle.

Meto Machinery specializes in producing a series of Drinking water bottle blowing machines with fast speed, good quality, high efficiency, and suitable for blowing various PET water bottles, including small bottles of 330-550ml mineral water bottles, 550-750ml drinking water plastic bottles, 1000-2000ml large bottles of pure water bottles and so on.

The blowing machines are convenient, fast, and have a large production capacity, suitable for various sizes of water plants, beverage companies, and other blown bottle applications.

Suitable for all shapes of PET plastic bottles,widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc

6 Cavity Full Automatic Blow Moulding Machine, with production capacity at 6,000~7,000 bottles per hour, is suitable for large water production line

PET blowing machine for 2l linear bottle blowing machines are used in the production of PET water bottles, hot filling bottles, carbonated beverage bottles, edible oil bottles, and pesticide bottles.

Drinking Water blow molding machines series is a stable two-step blow-down stretch automatic blowing machine.It can be used from 4 cavity to 8 cavity with a speed of 1500 bottles per cavity In one hour(750 ml plastic bottles),max volume 2L plastic bottle,suitable for blowing any kind of carbonated beverage bottle,sparkling beverage bottle,pure water bottle, mineral water bottle,fruit juice beverage bottle,cosmetic bottles,large diameter bottles, high temperature resistance bottles and other packaging bottles.

| Item | Meto-4 | Meto-6 | Meto-8 | |

|---|---|---|---|---|

| Bottle type specification | Cavity | 4 | 6 | 8 |

| Theory output | 8000-1000BPH | 12000-15000BPH | 16000-20000BPH | |

| Max.volume | 2L | 2L | 2L | |

| Bottle mouth maximum overall diameter | 28-38mm | 28-38mm | 28-38mm | |

| Bottle biggest diameter | 100mm | 100mm | 100mm | |

| Bottle maximun height | 330mm | 330mm | 330mm | |

| Power specification | Light tube quantity | 16pcs | 32pcs | 32pcs |

| Light tube power | 1.25KW | 1.25KW | 1.5KW | |

| Maximum heating pwoer | 20KW | 40KW | 48KW | |

| All electric machine installtion | 29KW | 49KW | 65KW | |

| Actual consumption | 30%-60% | 30%-60% | 30%-60% | |

| Air pressure specification | Work pressure | 5-6kg/cm² | 5-6kg/cm² | 5-6kg/cm² |

| Blow bottle pressure | 25-45kg/cm² | 25-45kg/cm² | 25-45kg/cm² | |

| Higher-pressure ges consumption | 6000Ltr/min | 8000Ltr/min | 12000Ltr/min | |

| Forzen water specification | Work pressure | 5-6 kg/cm² | 5-6 kg/cm² | 5-6 kg/cm² |

| Temperature range | 10℃ | 10℃ | 10℃ | |

| Consumption | 8000kcal/hr | 8000kcal/hr | 12000kcal/hr | |

| Forzen water flow | 88L/min | 120L/min | 150L/min | |

| Machine specification | Size of the machine | 3.6×1.6×1.9 | 4.8×1.8×1.9 | 5.78×1.6×1.9 |

| Weight of the machine | 4.3ton | 6.1ton | 7.45ton |

The machine shows characteristics such as high intelligence,stable and reliable mechanical performance, high production efficiency,low cost and pollution free from intermediate process,it is widely used for production of food,drink,cosmetic and medical vessel.

URL of this article: https://www.metomachinery.com/Application/Drinking-Water-Bottle.html

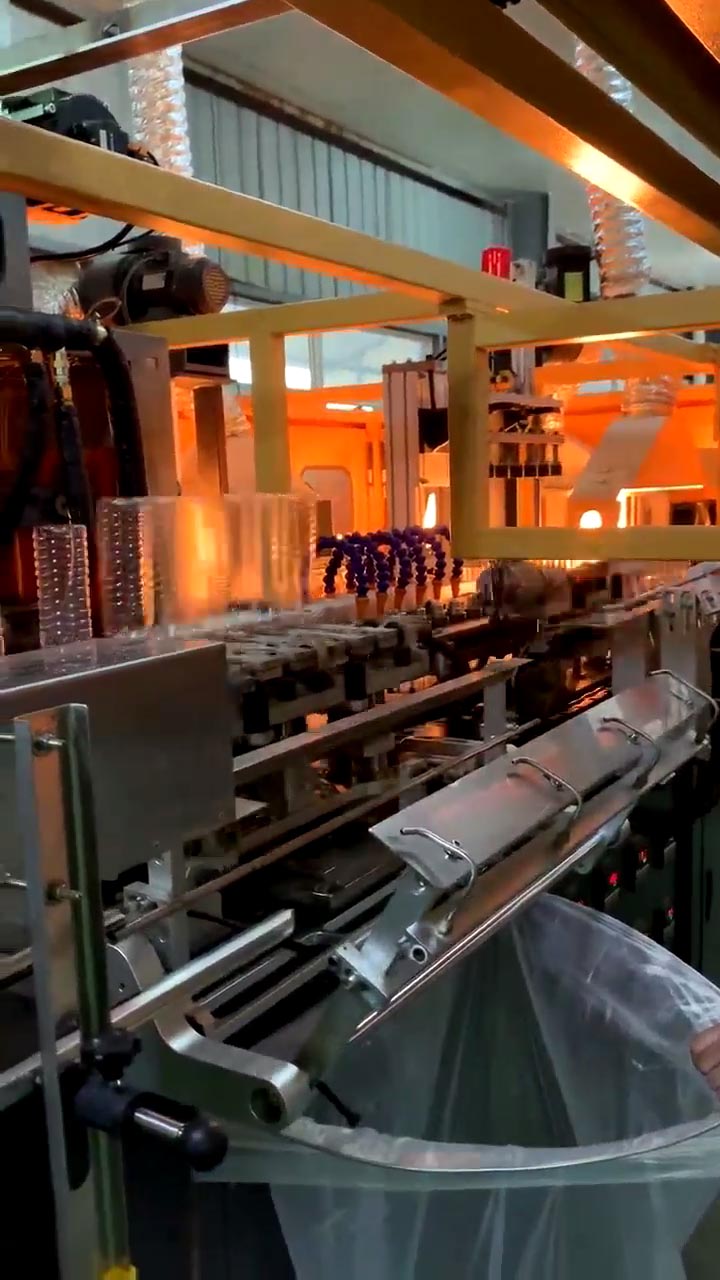

Bottle blowing machine video

Helpline and Support

008613757660057