Daily Chemistry Bottle

Daily Chemistry Bottle

2024/3/27 , visitsBlowing 2.0 liters, suitable for blowing any shape of cosmetic bottles, washing liquid bottles, shampoo bottles, skin care bottles, disinfectant bottles, disinfectant water bottles, medical alcohol bottles, alcohol bottles made of crystalline plastics such as PET and PP. Hand sanitizer bottles, hand sanitizer bottles and other packaging containers, etc. The H series bottle blowing machine does not have an automatic conveyor to transport the preforms (tubes), and the preforms can only be inserted manually. Advantages: The production cost of the machine is reduced to the greatest extent; the scrap rate is lower than that of the semi-automatic bottle blowing machine, the production speed is fast, the performance is stable, and the operation is extremely simple.

Looking for a reliable and efficient solution for producing PET jars? Look no further than METO 2 Cavity 5L PET Jars Blow Molding Machine, available for sale at factory direct pricing.

Suitable for all shapes of PET plastic bottles,widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc

6 Cavity Full Automatic Blow Moulding Machine, with production capacity at 6,000~7,000 bottles per hour, is suitable for large water production line

shampoo bottle making machines 2000ml

Fully automatic,low investment,high efficiency,easy operation, simple maintenance and safety.

Servo transmission system,high positioning accuracy, fast speed and stability, good reliability.Gas circuit design will divide action and blowing into three parts to meet the needs of different pressure for blowing bottles and movement;Adopt high pressure and double crank arm link locking,strong clamping force.

High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

use the air cylinder to avoid contamination and noise.

| Ltem | 2L-4 | |

| Bottle type specification | Cavity | 4 |

| Theory output | 4500-5000BPH | |

| Max.volume | 2L | |

| Bottle mouth maximum overall diameter | 28-38mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximun height | 330mm | |

| Power specification | Light tube quantity | 32pcs |

| Light tube power | 1.25KW | |

| Maximum heating pwoer | 40KW | |

| All electric machine installtion | 43KW | |

| Actual consumption | 30%--60% | |

| Air pressure specification | Work pressure | 7-9kg/cm2 |

| Low-pressure gas consumption | 1600L/min | |

| Blow bottle pressure | 25-35kg/cm2 | |

| Higher-pressure ges consumption | 3000Ltr/min | |

| Forzen water specification | Work pressure | 5-6 kg/c㎡ |

| Temperature range | 10℃ | |

| Consumption | 8000kcal/hr | |

| Forzen water flow | 88L/min | |

| Machine specification | Size of the machine | 4.1x1.6x1.9 |

| Weight of the machine | 3.5ton |

URL of this article: https://www.metomachinery.com/Application/Daily-Chemistry-Bottle.html

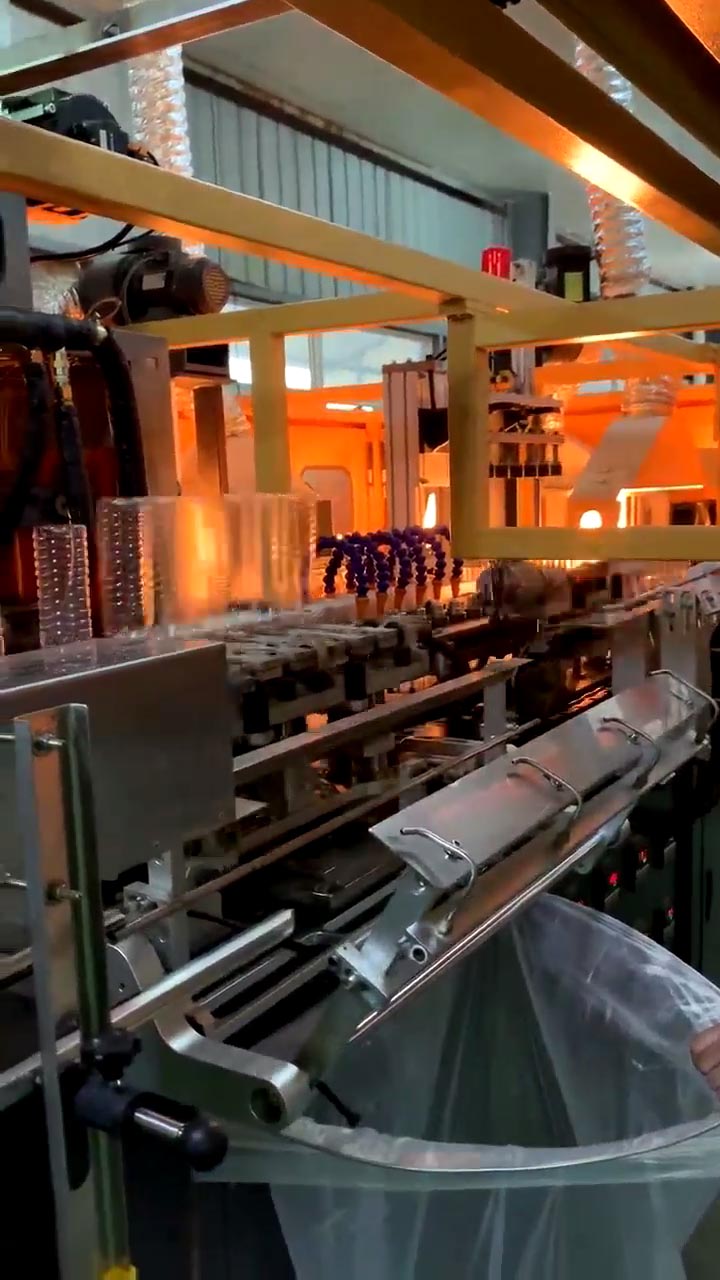

Bottle blowing machine video

Helpline and Support

008613757660057